The Alibaba Cloud 2021 Double 11 Cloud Services Sale is live now! For a limited time only you can turbocharge your cloud journey with core Alibaba Cloud products available from just $1, while you can win up to $1,111 in cash plus $1,111 in Alibaba Cloud credits in the Number Guessing Contest.

By Alibaba Cloud Research Center

In the next five years, China's manufacturing industry will usher in a new era of installation periods for the new digital infrastructure and the Industrial Internet. The organizations shaped by the digital infrastructure will also be redefined.

How can we use data collaboration to promote seamless collaboration within an organization? How can we make real-time and online decisions that are driven by data instead of managers' experience? How can we stimulate the data-driven operations and innovative thinking of all employees? DingTalk, an intelligent mobile working platform, has the answers to those questions.

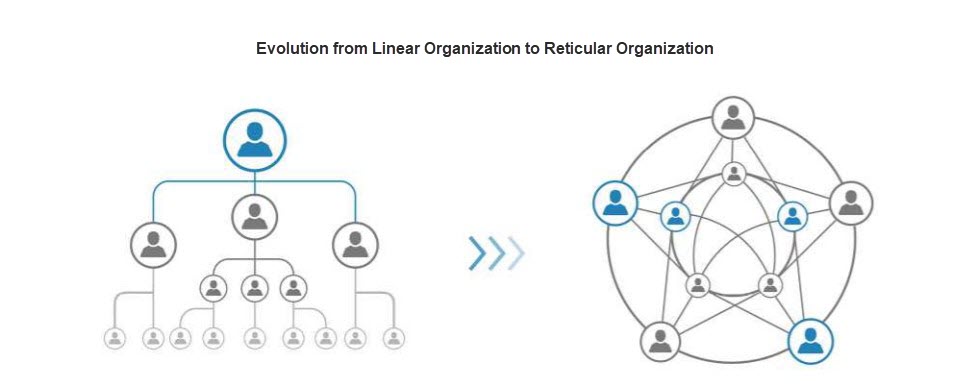

The greatest impact of the Industrial Internet on enterprises is the expansion and reconstruction of their organizational boundaries. Due to the scale, breadth, and complexity of the industrial Internet, the collaboration among organizations, employees, partners, and clients needs to be built on a more flat, decentralized, and networked "liquid organization." This is the only way enterprises can optimize decision-making efficiency and response speed, activate individual value, and finally realize the synchronization with the changes in external environments. As an organizational language, technology can efficiently integrate numerous members and resources into a "big system" and reconstruct the labor division and coordination system of the organization.

Enterprises need to quickly respond to the changing needs of the organizations, including requirements, scenarios, and roles. Enterprises also need to strengthen collaborative management to achieve optimal system efficiency. DingTalk is a new open platform based on the digital middle platform of Alibaba Cloud. It has evolved from a closed technology system to an open technology system. Secondly, it promotes enterprises to change from internal resource optimization to the collaborative optimization of the whole industrial chain. Thirdly, it serves as a new carrier for the transformation from a PC-based business system to a mobile system. Thus, it effectively supports the operations of online organizations, online communication, online collaboration, online business, and online ecosystems.

The biggest feature of an intelligent organization is to make real-time responses to changes in the external environment. For DingTalk, it is easy to achieve cross-departmental and cross-regional cooperation within the enterprise, as well as cooperation between enterprises and suppliers, vendors, partners, and clients. Based on the technical architecture of such a cloud platform, DingTalk is transforming a closed and rigid organizational architecture into an open and decentralized architecture.

Take Robam as an example. Robam uses DingTalk to connect the retail side and the manufacturing side, change the situation where all kinds of software and data are mixed, and promote the construction of the new manufacturing system of C2M. With DingTalk, Robam has realized the centralized presentation and real-time update of various data from sales, production, and finance. The management personnel can adjust the production, warehousing, and logistics in real-time according to the sales situation and conduct real-time actions to optimize the production and sales chain.

Before using DingTalk, data was stored and presented separately in different software for management. This makes it impossible to provide a unified decision basis. High ranking managers require more applications for management. As a result, it is difficult to remember all of the accounts and passwords. By taking advantage of DingTalk, Robam has realized the centralized presentation and real-time update of data from sales, production, and finance. Thus, managers can make timely judgments and decisions based on sufficient data.

The management personnel can adjust production, warehousing, and logistics in real-time according to the sales situation and conduct real-time actions to optimize the production and sales chain. For scenarios, such as Double 11 and Double 12, with much work to do within a limited time, the ability to make precise and efficient decisions plays a critical role in business.

Nowadays, how an organization creates value and helps others create value is an important way to show its vitality of innovation. DingTalk provides a brand-new technical support and operation system for enterprises. Through DingTalk, enterprises can easily and efficiently create, operate, and manage organizations in a complex network that includes the whole industry chain and business scenarios.

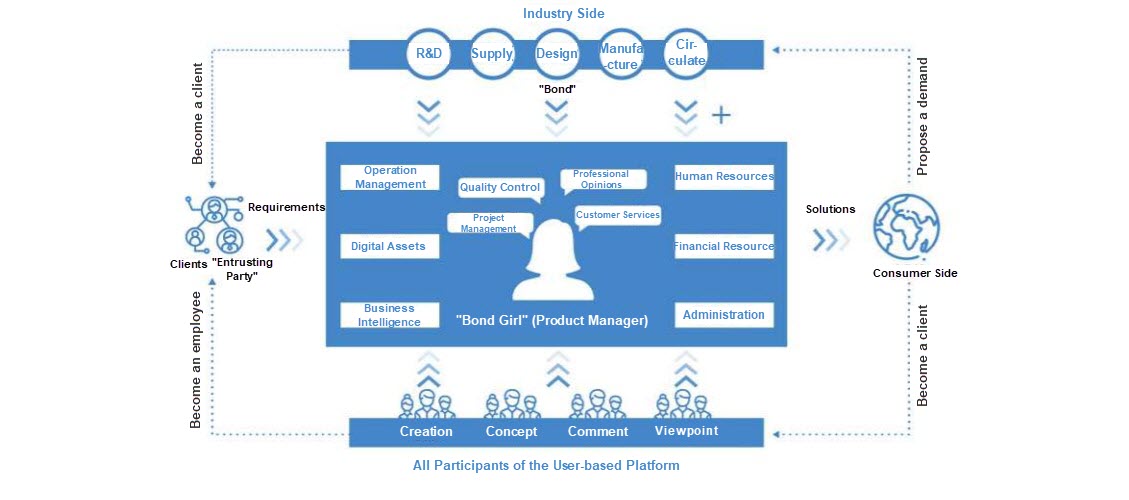

Take the LKKER, a shared platform designed by LKK Design, as an example. Designers, brands, and community users can accurately match other designers and users in the community through the LuoDingDing platform, and their personalized demands can be met. The LKKER is a platform for nearly 40,000 registered designers, millions of users, and 3,000 cooperative brands. Faced with such a huge ecosystem, the LuoDingDing platform can shorten the average delivery cycle from design to R&D to 30 days from the original three months.

DingTalk has built an architecture system with a large middle platform and a small frontend for enterprises. Based on the concept of people-oriented design, it breaks the traditional process-based mode and builds task-oriented and scenario-oriented modes for real-time, online collaboration of multiple agents. By doing so, it promotes the transformation from series calibration to parallel calibration between organizations. It also accelerates the evolution of the traditional organizational structure towards the "large middle platform and small frontend" architecture.

Take Robam as an example again. The company launched an initiative to write DingTalk logs. It began from the management layer and then to the entire company. The content of logs is no longer a document-kind work report, but instead, it records everyone's thoughts. In the process of communication of various thoughts, colleagues can understand each other's work progress and expand the discussion. While the organizational boundaries are expanded, the ideological unity and common governance of the whole company have been realized.

A series of new manufacturing concepts, such as digital factory, IT/OT integration, and digital twin, interpret the value brought by online/offline collaboration to production and operation. They are all developed around the industrial Internet. As an ideal mobile medium, DingTalk can connect the digital field and physical field and trade time for space. It can also break down mutual barriers between people and machines and create a seamless "social factory." Thus, it can make decision-making more efficient and accurate.

Take East Hope Group, one of the top 500 manufacturing companies in China, as an example. Traditionally, management and control of factory production require offline control of the operation desk and personnel inspection. However, when using DingTalk micro-applications on the DingTalk platform, such as systems for MES, equipment management, fault maintenance, and tickets management, those who are responsible for production can check production data and indicators online. They can also perform fault handling offline. Therefore, the workspace is extended while work efficiency is greatly improved.

During the COVID-19 pandemic, Hongda Motor used DingTalk applets to manage the disinfection and sterilization of 200 pieces of processing equipment and wire cutting machines in the factory. The workshop directors and device examiners can scan the QR code on each device to view the disinfection information about the device and the related production area. The information is summarized and reported in real-time and approved online, which greatly improves productivity.

DingTalk has brought great values as a platform leader and a driving force in the era of digital transformation 2.0. The biggest value lies in reconstructing the forms of communication, optimizing collaboration methods, and promoting organizational changes. It launches and supports a "transgenic project" at the organizational layer. DingTalk realizes efficient collaboration across departments within the enterprise and also creates a platform to connect suppliers to other suppliers, distributors, agents, and consumers.

2,593 posts | 792 followers

FollowAlibaba Clouder - July 23, 2021

Alibaba Clouder - October 14, 2020

Alibaba Cloud Community - February 4, 2022

Alibaba Cloud Community - May 30, 2022

Alibaba Clouder - April 9, 2020

Alibaba Cloud Native Community - November 23, 2022

2,593 posts | 792 followers

Follow IoT Platform

IoT Platform

Provides secure and reliable communication between devices and the IoT Platform which allows you to manage a large number of devices on a single IoT Platform.

Learn More Black Friday Cloud Services Sale

Black Friday Cloud Services Sale

Get started on cloud with $1. Start your cloud innovation journey here and now.

Learn More IoT Solution

IoT Solution

A cloud solution for smart technology providers to quickly build stable, cost-efficient, and reliable ubiquitous platforms

Learn MoreMore Posts by Alibaba Clouder