Artificial intelligence (AI) is everywhere. We use it often in our daily lives without even noticing. Over the years, AI has progressed a lot, affecting many industries with its improvement in processing, algorithms, and data storage. Machine learning, which provides data for analysis and key insights, has a huge impact on manufacturing.

The four ways AI impacts manufacturers are listed below:

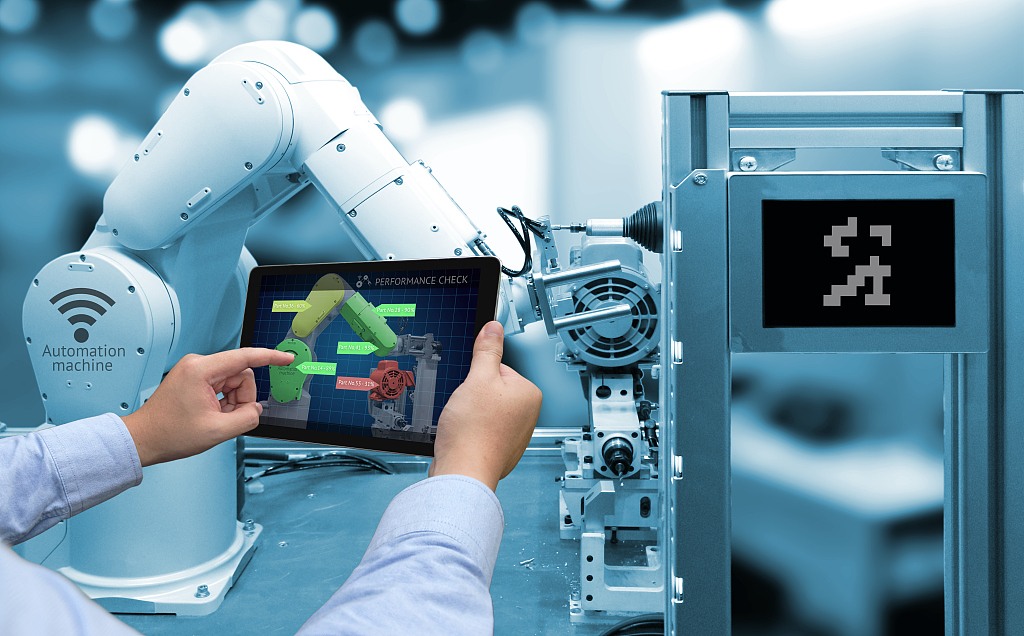

Collaborative robots (cobots) are designed to cooperate safely with human beings. Small and lightweight cobots provide a more affordable option for manufacturers interested in developing robotics. Another advantage lies in their ability to help create a safer working environment by performing dangerous tasks that usually lead to work injuries. With the help of AI, jobs will be less onerous for workers, and more complex tasks can be performed without harming employees.

Using robots in the workplace may bring about problems, such as how programmed robots respond to unexpected situations, but machine learning can fix many of them. With pattern recognition and data analysis, machine learning can teach system self-learning and self-improvement without targeted programming.

You can reach the highest standards based on customer satisfaction and customer reputation. With the help of AI, manufacturers can be informed of any quality-related problems with their products or services. Failures, whether major or minor, can be solved using AI technologies, and many problems can be avoided in the early stage.

Machine vision is a good example of an AI solution. It monitors defects and other potential problems with high-definition cameras better than human monitoring. By using machine vision, the performance data of products or services can be collected for manufacturers to make better future decisions.

Since the 1960s, unmanned aerial vehicles (UAVs) and industrial robots have been applied to the manufacturing industry. Manufacturers can explore new possibilities with the support of AI. For example, generative design is a great way for engineers to produce thousands of design outputs. It is a perfect solution to put forward various plans for customers quickly and efficiently.

Machine learning can help generate inventory plans with its ability to forecast supply plans. Compared with traditional demand forecasting methods, AI tools are more accurate. Thus, manufacturers can manage inventory more effectively to lower the likelihood of accidents.

In general, AI is beneficial when it comes to manufacturing. It generates more product innovation and provides safer precautions, a faster decision-making process, and quality improvement. AI gives manufacturers a clear vision of how to make improvements.

This article is retrieved and translated from Qianjia: http://www.qianjia.com/html/2021-05/14_378455.html

Disclaimer: The views expressed herein are for reference only and don't necessarily represent the official views of Alibaba Cloud.

2,593 posts | 791 followers

FollowAlibaba Clouder - October 15, 2018

Alibaba Cloud Industry Solutions - January 10, 2022

Amuthan Nallathambi - July 12, 2024

Alibaba Clouder - April 29, 2020

Alibaba Clouder - February 4, 2020

Ashish-MVP - April 8, 2025

2,593 posts | 791 followers

Follow Platform For AI

Platform For AI

A platform that provides enterprise-level data modeling services based on machine learning algorithms to quickly meet your needs for data-driven operations.

Learn More Epidemic Prediction Solution

Epidemic Prediction Solution

This technology can be used to predict the spread of COVID-19 and help decision makers evaluate the impact of various prevention and control measures on the development of the epidemic.

Learn More Online Education Solution

Online Education Solution

This solution enables you to rapidly build cost-effective platforms to bring the best education to the world anytime and anywhere.

Learn More Accelerated Global Networking Solution for Distance Learning

Accelerated Global Networking Solution for Distance Learning

Alibaba Cloud offers an accelerated global networking solution that makes distance learning just the same as in-class teaching.

Learn MoreMore Posts by Alibaba Clouder